靜電(dian)(dian)除塵(chen)器的(de)電(dian)(dian)源由控制箱、升壓變壓器和整流(liu)器組(zu)成。電(dian)(dian)源輸出的(de)電(dian)(dian)壓高低對除塵(chen)效率也有很大影響。因(yin)此(ci),靜電(dian)(dian)除塵(chen)器運行電(dian)(dian)壓需保(bao)持(chi)40一75kV乃至100kV以上(shang)。

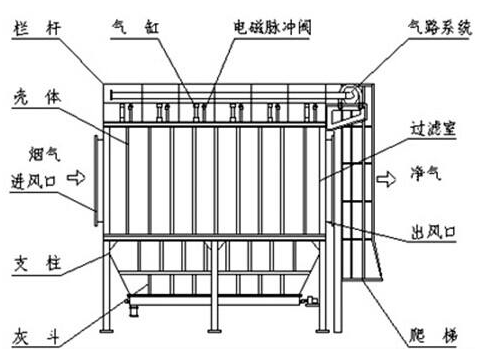

基本結構

靜(jing)電(dian)(dian)(dian)(dian)電(dian)(dian)(dian)(dian)除(chu)塵(chen)器(qi)由(you)兩大(da)部(bu)分(fen)組成:一部(bu)分(fen)是電(dian)(dian)(dian)(dian)除(chu)塵(chen)器(qi)本體系(xi)統(tong)(tong);另一部(bu)分(fen)是提供(gong)高壓(ya)(ya)直流電(dian)(dian)(dian)(dian)的供(gong)電(dian)(dian)(dian)(dian)裝置和低壓(ya)(ya)自動控(kong)制系(xi)統(tong)(tong)。電(dian)(dian)(dian)(dian)除(chu)塵(chen)器(qi)的結構原(yuan)理圖如圖1所示,高壓(ya)(ya)供(gong)電(dian)(dian)(dian)(dian)系(xi)統(tong)(tong)為升壓(ya)(ya)變壓(ya)(ya)器(qi)供(gong)電(dian)(dian)(dian)(dian),除(chu)塵(chen)器(qi)集塵(chen)*接地。低壓(ya)(ya)電(dian)(dian)(dian)(dian)控(kong)制系(xi)統(tong)(tong)用來控(kong)制電(dian)(dian)(dian)(dian)磁(ci)振打錘、卸灰電(dian)(dian)(dian)(dian)*、輸灰電(dian)(dian)(dian)(dian)*以及幾個(ge)部(bu)件的溫度。

工作原理

電(dian)除塵器(qi)的(de)基本原(yuan)理(li)是利用電(dian)力捕集煙氣(qi)中的(de)粉(fen)塵,主要包括(kuo)以下四個(ge)相互有關(guan)的(de)物理(li)過程:(1)氣(qi)體的(de)電(dian)離。(2)粉(fen)塵的(de)荷電(dian)。(3)荷電(dian)粉(fen)塵向電(dian)*移動。(4)荷電(dian)粉(fen)塵的(de)捕集。

荷(he)電(dian)(dian)(dian)(dian)粉(fen)塵(chen)的(de)捕集過(guo)程:在(zai)兩(liang)個(ge)曲率半徑相差較大的(de)金屬陽(yang)*和陰(yin)*上(shang),通過(guo)高壓直流(liu)電(dian)(dian)(dian)(dian),維持一個(ge)足(zu)以使氣體(ti)電(dian)(dian)(dian)(dian)離(li)(li)的(de)電(dian)(dian)(dian)(dian)場,氣體(ti)電(dian)(dian)(dian)(dian)離(li)(li)后所產生的(de)電(dian)(dian)(dian)(dian)子:陰(yin)離(li)(li)子和陽(yang)離(li)(li)子,吸附(fu)在(zai)通過(guo)電(dian)(dian)(dian)(dian)場的(de)粉(fen)塵(chen)上(shang),使粉(fen)塵(chen)獲得電(dian)(dian)(dian)(dian)荷(he)。荷(he)電(dian)(dian)(dian)(dian)*性不同(tong)的(de)粉(fen)塵(chen)在(zai)電(dian)(dian)(dian)(dian)場力的(de)作用下,分別向不同(tong)*性的(de)電(dian)(dian)(dian)(dian)*運動,沉積(ji)在(zai)電(dian)(dian)(dian)(dian)*上(shang),而達到(dao)粉(fen)塵(chen)和氣體(ti)分離(li)(li)的(de)目的(de)。

特點

靜電除(chu)(chu)塵(chen)(chen)器與其(qi)他除(chu)(chu)塵(chen)(chen)設備相比,耗能少,除(chu)(chu)塵(chen)(chen)效(xiao)率高,適用(yong)(yong)于除(chu)(chu)去煙(yan)(yan)氣中0.01—50μm的粉塵(chen)(chen),而且可用(yong)(yong)于煙(yan)(yan)氣溫度高、壓力大(da)的場合。實踐表明,處理的煙(yan)(yan)氣量越大(da),使(shi)用(yong)(yong)靜電除(chu)(chu)塵(chen)(chen)器的投資(zi)和運行費(fei)用(yong)(yong)越經濟。

寬間距臥式電除塵器技術

HHD型寬(kuan)間距臥式電除(chu)塵器是引進和(he)借鑒國外**技術,結合中國各(ge)行業(ye)工業(ye)窯爐廢氣工況的(de)特點,為適應日趨嚴格的(de)廢氣排(pai)放要求和(he)WTO市場準則研(yan)究開發的(de)科研(yan)成果。該(gai)成果已廣泛應用在(zai)冶金、電力(li)、水泥等行業(ye)。

寬間距及*板特別配置

使(shi)得(de)電場(chang)場(chang)強、板電流分布更加均勻,驅進速(su)度可提高(gao) 1.3倍,使(shi)捕集(ji)粉(fen)塵比電阻范圍(wei)擴大到(dao)10 1 -10 14 Ω-cm,特別適用于硫化床(chuang)鍋爐、新型(xing)水泥干法(fa)回轉(zhuan)窯、燒結(jie)機(ji)等廢氣的(de)高(gao)比電阻粉(fen)塵回收,減緩或消除反(fan)電暈現象。

整體新型RS電暈線

長度(du)(du)(du)可(ke)達(da)15米,具有起(qi)暈電壓(ya)低,電暈電流密度(du)(du)(du)大,鋼性強,永不破(po)損,具有抗高溫(wen)、抗熱變能力(li),結合頂部振打方式清灰效果*佳(jia)。根據粉塵濃(nong)度(du)(du)(du)大小配置相(xiang)應(ying)(ying)的(de)電暈線密度(du)(du)(du),從而可(ke)適應(ying)(ying)高粉塵濃(nong)度(du)(du)(du)的(de)收塵,允許入口濃(nong)度(du)(du)(du)可(ke)達(da)1000g/Nm 3。

電暈*頂部強力振打

根據清灰理論(lun)設(she)計的頂(ding)部放電*強力振打(da),可采用(yong)機械和電磁(ci)兩種任選(xuan)方式。

陰陽兩*自由懸吊

HHD電(dian)收塵器(qi)收塵系統和電(dian)暈*系統均采用三維懸吊結構,當廢氣溫(wen)(wen)度過高時,收塵*和電(dian)暈*將(jiang)按(an)三維方向任意(yi)膨脹伸展,收塵*系統還特別設計了抗(kang)熱變鋼帶約(yue)束結構,使得HHD電(dian)收塵器(qi)具有較高的抗(kang)熱變能力,經商業(ye)運行表(biao)明,HHD電(dian)收塵器(qi)耐溫(wen)(wen)可達390℃。

提高振打加速度

改(gai)善(shan)清(qing)灰(hui)(hui)效果(guo) :收塵(chen)*系統清(qing)灰(hui)(hui)好壞直接影響收塵(chen)效率(lv),大部(bu)(bu)分電收器(qi)在經過一段(duan)時(shi)間運行后都(dou)表(biao)現出效率(lv)下降(jiang)情況,究其根源主要是收塵(chen)*板清(qing)灰(hui)(hui)效果(guo)差(cha)所致, HHD電收塵(chen)器(qi)利用撞擊理論和實踐結果(guo),改(gai)傳(chuan)統扁鋼撞擊桿結構為整(zheng)體型鋼結構,又將收塵(chen)*的側(ce)部(bu)(bu)振(zhen)打錘(chui)結構刪繁就簡(jian),使(shi)掉錘(chui)環節(jie)減少2/3,實驗表(biao)明收塵(chen)*板面加速度從220G提高到356G。

占地面積小、重量輕

由于放電*系統采用(yong)頂部振打設(she)計(ji),且打破常規創造性地將每個電場采用(yong)非對稱懸吊設(she)計(ji),并利用(yong)美國(guo)環(huan)境設(she)備公司殼體(ti)計(ji)算機軟(ruan)件優化設(she)計(ji),使得在同樣收塵(chen)總面積的情況,電收塵(chen)器總體(ti)長度減少3-5米,重量減輕(qing)15%。

高保證絕緣系統

為(wei)防(fang)止電(dian)除塵器的高(gao)壓絕緣(yuan)材料結(jie)露(lu)爬(pa)電(dian),殼(ke)體采(cai)用(yong)蓄熱雙層充氣屋(wu)頂設(she)計(ji),電(dian)加熱采(cai)用(yong)新PTC、PTS材料,絕緣(yuan)套(tao)管底部采(cai)用(yong)雙曲線反吹(chui)清掃設(she)計(ji),徹底杜絕了瓷套(tao)管結(jie)露(lu)爬(pa)電(dian)的易發故障,且維(wei)護、保養、更換*為(wei)便利。

匹配L-C高系統

高(gao)壓控制(zhi)可(ke)采用(yong) DSC系統控制(zhi),上位機操(cao)作,低壓控制(zhi)采用(yong)PLC控制(zhi), 中文觸(chu)摸(mo)屏操(cao)作。高(gao)壓電(dian)源(yuan)采用(yong)恒電(dian)流、高(gao)阻抗直(zhi)流電(dian)源(yuan),匹配 HHD電(dian)收(shou)塵器(qi)本體。可(ke)產生高(gao)除塵效率、克(ke)服高(gao)比電(dian)阻、處理(li)高(gao)濃度的優越功能。

影響除塵效果的因素

除(chu)塵(chen)器的除(chu)塵(chen)效(xiao)果(guo)與(yu)許(xu)多因(yin)素有關,如煙氣的溫度、流速,以及(ji)除(chu)塵(chen)器的密封狀態、收(shou)塵(chen)板間距等。

2.1煙氣的溫度

煙(yan)氣(qi)的(de)(de)溫(wen)度(du)過高,電(dian)(dian)暈(yun)(yun)始發電(dian)(dian)壓(ya)、起暈(yun)(yun)時電(dian)(dian)暈(yun)(yun)*表面的(de)(de)電(dian)(dian)場溫(wen)度(du)、火花放電(dian)(dian)電(dian)(dian)壓(ya)等(deng)均降(jiang)低(di),影響除塵效率。煙(yan)氣(qi)的(de)(de)溫(wen)度(du)過低(di),容易造成絕緣(yuan)部件因結露而爬電(dian)(dian);金屬件被腐(fu)蝕,并且燃(ran)煤發電(dian)(dian)排出(chu)的(de)(de)煙(yan)氣(qi)中含有SO2,其腐(fu)蝕程度(du)更為嚴重(zhong);灰(hui)斗(dou)內粉塵結塊影響排灰(hui),該廠曾因灰(hui)斗(dou)長期(qi)積灰(hui),使收塵板、電(dian)(dian)暈(yun)(yun)線(xian)(xian)埋(mai)于積灰(hui)中而將收塵板燒變形,斷裂,電(dian)(dian)暈(yun)(yun)線(xian)(xian)燒斷。

2.2煙(yan)氣的(de)流速

過(guo)(guo)高(gao)煙氣(qi)(qi)的流(liu)速不能(neng)過(guo)(guo)高(gao),因為粉(fen)塵(chen)在(zai)電場中荷(he)電后沉積(ji)島收塵(chen)*上需要有一定的時(shi)間,如果煙氣(qi)(qi)風速過(guo)(guo)高(gao),核電粉(fen)塵(chen)來(lai)不及沉降(jiang)就被氣(qi)(qi)流(liu)帶出(chu),同時(shi)煙氣(qi)(qi)的流(liu)速過(guo)(guo)高(gao)容易使已沉積(ji)在(zai)收塵(chen)板上的粉(fen)塵(chen)產生(sheng)二次飛(fei)揚(yang),特別是振打落灰時(shi)更容易產生(sheng)二次飛(fei)揚(yang)。

2.3板間距

當作用電(dian)壓(ya)、電(dian)暈線的(de)(de)間距(ju)(ju)和半徑(jing)相同時(shi),加大(da)板(ban)間距(ju)(ju),會影響電(dian)暈線臨近區所產(chan)生離子電(dian)流(liu)的(de)(de)分(fen)布、增大(da)表面積上的(de)(de)電(dian)位差(cha),將導致電(dian)暈外區電(dian)場強度降低,影響除塵效率。

2.4電暈線(xian)間(jian)距

電(dian)(dian)(dian)(dian)(dian)暈(yun)線的(de)間距有一個會產生大(da)電(dian)(dian)(dian)(dian)(dian)暈(yun)電(dian)(dian)(dian)(dian)(dian)流的(de)佳值,當作(zuo)用電(dian)(dian)(dian)(dian)(dian)壓、電(dian)(dian)(dian)(dian)(dian)暈(yun)線半徑和(he)板間距相同(tong)時,增大(da)電(dian)(dian)(dian)(dian)(dian)暈(yun)線間距會使電(dian)(dian)(dian)(dian)(dian)暈(yun)電(dian)(dian)(dian)(dian)(dian)流密度和(he)電(dian)(dian)(dian)(dian)(dian)場(chang)強度的(de)分(fen)布(bu)不均勻,若電(dian)(dian)(dian)(dian)(dian)暈(yun)線間距小于佳值,電(dian)(dian)(dian)(dian)(dian)暈(yun)線附(fu)近電(dian)(dian)(dian)(dian)(dian)場(chang)的(de)相互屏蔽作(zuo)用會使電(dian)(dian)(dian)(dian)(dian)暈(yun)電(dian)(dian)(dian)(dian)(dian)流減小。

2.5氣流分布不勻(yun)

出現(xian)氣(qi)流(liu)分布不勻時,氣(qi)流(liu)速(su)(su)(su)度(du)(du)(du)低(di)(di)的地(di)方(fang)收(shou)塵(chen)率高(gao),氣(qi)流(liu)速(su)(su)(su)度(du)(du)(du)高(gao)的地(di)方(fang)收(shou)塵(chen)率低(di)(di),氣(qi)流(liu)速(su)(su)(su)度(du)(du)(du)低(di)(di)的地(di)方(fang)增(zeng)加(jia)的粉塵(chen)收(shou)集量(liang)小于氣(qi)流(liu)速(su)(su)(su)度(du)(du)(du)高(gao)的地(di)方(fang)減(jian)少(shao)的粉塵(chen)收(shou)集量(liang),而(er)總收(shou)塵(chen)效率降低(di)(di)。并且氣(qi)流(liu)速(su)(su)(su)度(du)(du)(du)高(gao)的地(di)方(fang)會出現(xian)沖刷現(xian)象,將已沉積(ji)在收(shou)塵(chen)板上的粉塵(chen)再次(ci)大量(liang)揚起(qi)。

2.6漏風

由(you)于電(dian)除(chu)(chu)(chu)塵(chen)(chen)(chen)(chen)器用(yong)于負壓(ya)操(cao)作,如果(guo)殼體的(de)連(lian)接處(chu)密(mi)封不(bu)嚴(yan),就會從(cong)外部漏入(ru)冷空(kong)(kong)氣,使(shi)通過電(dian)除(chu)(chu)(chu)塵(chen)(chen)(chen)(chen)的(de)風速增大(da)(da)(da),煙氣溫(wen)(wen)(wen)度降低,這會使(shi)煙氣露點(dian)發生變化,使(shi)收(shou)塵(chen)(chen)(chen)(chen)性(xing)能下(xia)降,如果(guo)從(cong)灰斗(dou)或排灰裝置漏入(ru)空(kong)(kong)氣,將會造(zao)成(cheng)收(shou)下(xia)的(de)粉(fen)塵(chen)(chen)(chen)(chen)產生再飛揚(yang),使(shi)收(shou)塵(chen)(chen)(chen)(chen)效(xiao)(xiao)率降低,還會使(shi)灰受潮、粘附灰斗(dou)造(zao)成(cheng)卸(xie)灰不(bu)流暢(chang),甚至產生堵灰。陶二電(dian)廠的(de)1#、2#除(chu)(chu)(chu)塵(chen)(chen)(chen)(chen)器曾(ceng)因保溫(wen)(wen)(wen)室(shi)密(mi)封不(bu)嚴(yan)漏入(ru)大(da)(da)(da)量高(gao)溫(wen)(wen)(wen)熱(re)灰,不(bu)但除(chu)(chu)(chu)塵(chen)(chen)(chen)(chen)效(xiao)(xiao)果(guo)大(da)(da)(da)大(da)(da)(da)下(xia)降,而且許多保溫(wen)(wen)(wen)圈的(de)連(lian)接線燒壞。灰斗(dou)處(chu)也曾(ceng)因漏風使(shi)卸(xie)灰口結冰,卸(xie)不(bu)下(xia)灰來(lai),造(zao)成(cheng)灰斗(dou)內大(da)(da)(da)量積灰。

- 上一篇:氣箱脈沖袋式除塵器PPC96-8

- 下一篇:袋式除塵器